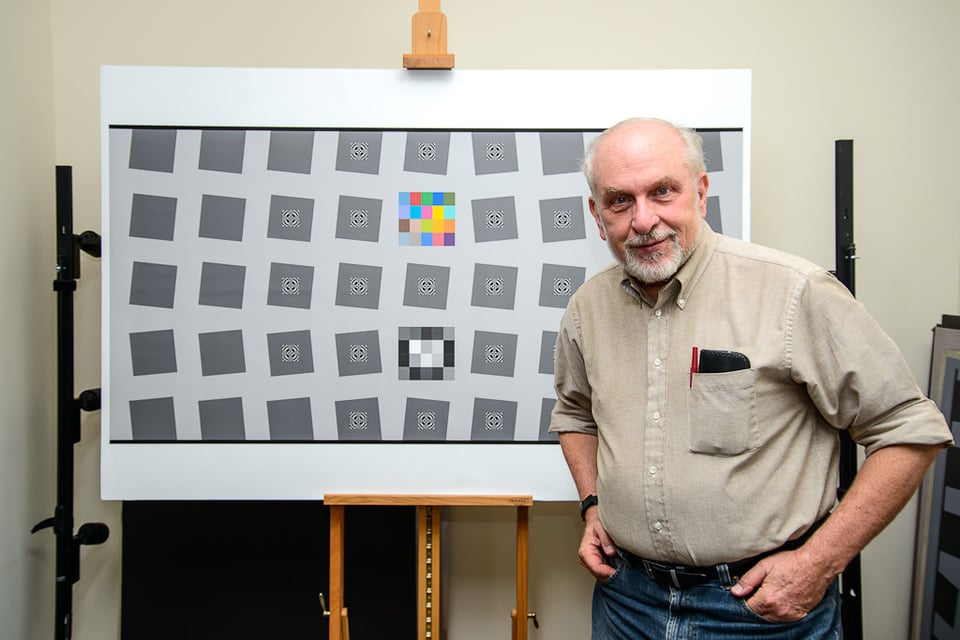

A couple of weeks ago I had an opportunity to visit Norman Koren, founder of Imatest, LLC. I have been fascinated by his software for a while now and after evaluating the software, decided to purchase it to use in our lens reviews. When I found out that his company is right here in Boulder, Colorado (where I lived for over 5 years), I gave him a call and asked if I could come over and interview him. Despite his busy and hectic schedule, he was able to accommodate me for an hour during his lunch time. Below is the text version of the interview.

Nasim: Thank you for giving us the opportunity to visit your office and learn more about you and your company. Let’s get started with your background, your company and how it all started.

Norman: You are most welcome Nasim. I grew up in Rochester, NY, about a mile from the George Eastman House, which I visited frequently. Both the technical and artistic exhibits made a deep impression on me—it was there that I first saw the beautiful prints of Ansel Adams and Edward Weston. I had a long career in magnetic recording technology, where my job involved simulating the performance of read, write, signal processing and detection in disk and tape drives. It started back in 1967 at Honeywell in Boston. I then worked for a number of companies including, curiously enough, Kodak in San Diego. Kodak at the time— we are talking 1985— believed that very small tape drives would be used in digital cameras. Well, it didn’t turn out to be a winning technology, but I had an interesting 12 years there. At the same time, I’ve always been a passionate photographer.

Nasim: I saw your landscape photos on your old website, they are beautiful.

Norman: Thank you, that website is out of date! I got quite interested in fine art photography when I was in college, but for a variety of reasons decided to pursue science for a career. Did a lot of darkroom work, made plenty of black and white prints, studied Ansel Adams very thoroughly and I have always enjoyed photography a great deal. When I moved to Colorado in 1998, I got into digital photography, which was a new technology that was just starting to evolve. Then in around 2000, after I had some trouble finding answers to photography questions — this was pre-Google and pre-Wikipedia — I decided to post some information on my website www.normankoren.com after figuring things out. I posted three pages with information on scanning, editing and printing, thinking that it would be all that anyone would ever need for digital photography.

Late in 2001, I lost my job at StorageTek. Fortunately, I had some savings, and I decided that I wasn’t going to go back to magnetic recording— I was going to do something with photography, like be a fine art photographer. But I couldn’t keep away from the technical side, since I’ve always been fascinated by technology. So in 2003, I started getting more and more involved in quality measurements. I wanted to find out what cameras and lenses were better than others. I then found out about what’s called a “slanted-edge method” of measuring MTF (Modulation Transfer Function), which is a measure of the sharpness of an image. It is actually kind of a frequency response – the more extended it is, the sharper the lens. It’s a much better measurement than the traditional “vanishing resolution” method. The founder of a certain well-known website read about what I was doing and asked me if I would do something to put some numbers to the images they were putting up on their website. So I spent the summer of 2003 developing the beginnings of Imatest. When I showed him the product, he offered me a ridiculously low price. But that’s another story. In any case, I got started in 2003 and over the next year I developed more of a commercially usable program. The original beta was command-line based and hard to use, but by the September 2004 release we have a convenient Graphic User Interface. It measured sharpness using a slanted edge, color accuracy using the X-Rite color checker and tonal response using Kodak Q13 or Q14 step charts. Since then, the product has grown enormously. We have added a tremendous number of features. I found out that my original estimate of the target market was totally wrong, which turned out to be good news. I thought it would be for geeky photographers like myself with a little bit of engineering background. But in fact, I started selling the product to a variety of large companies around the world…

Nasim: Can you name a few of those companies?

Norman: Yes, Intel, Google, Microsoft, Motorola, Nvidia, Cisco, Samsung, Sony…

Nasim: Wow, those are some big names. What did they want to use Imatest for?

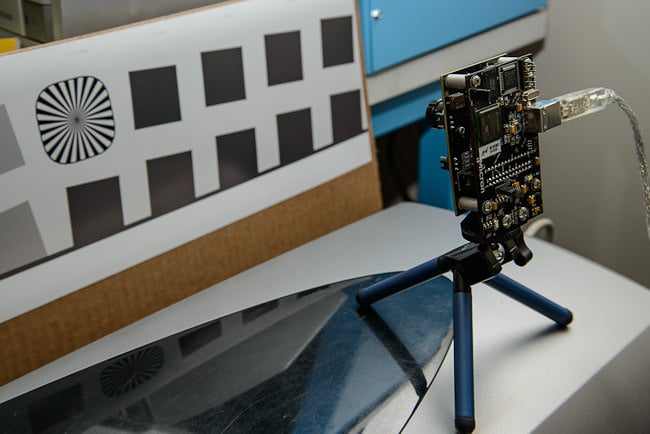

Norman: A huge variety of uses. For example, in the camera phone industry, there is a whole supply chain that goes from chips and other components to the handsets. And by some wonderful invisible hand, the whole supply chain is using Imatest, so the chip makers like Sony and Aptina are using Imatest to make sure that their chips can put out good signals with proper lenses. Lens makers and lens component makers are also using Imatest as a part of their evaluation and testing process.

Nasim: Can you name a few names in the lens making industry?

Norman: The names are not that big in lens making, because the two really big companies Nikon and Canon have their own software, which traditionally has been a part of their advantage. They are obviously not thrilled with having a small competitor, but we have sold a fair amount to companies like Panasonic. We occasionally sell to some of the bigger names, but not necessarily to their main factories. There are a number of review sites that are using us, like Imaging Resource and Photozone – those are two of the larger ones that are using us and there are a number of smaller ones, as well as some foreign language sites. We have a lot of medical customers for endoscopes and other types of medical equipment as well as aerospace and automotive companies. If you need to measure a lens by itself in fine detail, Imatest is not the way to go. But if you want to look at what a lens can do in a camera, what your bottom line is and what you are getting out of a system as a whole, then Imatest is a superb way of measuring it. And over the years we’ve simplified and automated the measurements. Right now we have a chart called SFRPlus, where you can take one picture and measure most of the key image quality parameters without selecting regions. It is highly automated and very efficient. The sharpness measurement is based on an ISO standard. We have refined it a great deal, but most of the details and the interface we have developed ourselves. We can measure optical distortion, lateral chromatic aberration, also known as color fringing, then we measure color response, tonal response. Noise measurements are pretty limited with SFRplus, but we do that in detail with other charts. We can also make a rough estimate of the ISO speed if you know the incident light on the chart. And those are the key things that we measure with our SFRPlus chart. We’ve also adapted it for industrial automation. The only things that SFRplus does not measure are light falloff, color uniformity and blemishes, which require a flat field— a featureless image.

Nasim: So field curvature cannot be measured?

Norman: Field curvature can only be measured indirectly, because what happens with field curvature is that the focus at the corners is quite different from the focus in the center. So if you focus in the center, you will see sharp center and fuzzy corners. If you focus in the corners, the center gets fuzzy. So by making several frames and adjusting the focus, we can see if there is curvature of field, but it is not an easy thing to measure. We don’t do any detailed reporting on other optical aberrations like astigmatism and coma – those simply show up as degradation of MTF or sharpness. You need point sources of light to measure those, just like for measuring ghosting and flare.

Nasim: So you first started out by creating a product that you were planning to sell to photographers and ended up creating a product that you sell to manufacturers? Is the plan to continue doing that or do you want to do both?

Norman: We will continue to sell Imatest Studio, which is a reduced functionality version that we sell to individual photographers or very small businesses. It’s quite low cost— it doesn’t have all the details of Master, but it has essentially everything you need to test out your camera and your lenses. The Master Edition that we sell to companies has a lot more detail that’s of interest to engineers who are designing systems. Our current plan is to continue development of these products. Our current development emphasis is on industrial automation, which we see as a good and healthy market . We can offer the same mathematical pass/fail routines on the production floor that our customers use in the laboratory for developing systems. My team member Henry has spent five weeks in China so far this year directly involved in implementing Imatest in manufacturing. We look forward to being able to boast about some of the products in the future— they are not yet on the market.

Nasim: Let’s talk about cameras. I would love to find out about your industry perspective. How do you see DSLRs in the future and what is your take on the mirrorless market?

Norman: There are only a small number of companies making SLRs today and I personally don’t see that number growing in the future. I think that mirrorless cameras will take over a huge chunk of the market share from DSLRs, but definitely not entirely. DSLRs have some advantages in terms of speed, sensor size and a few other things. I don’t see the DSLR market growing, but I don’t see it dying either. Whereas the low-end point and shoot market probably is going to die because of high quality camera phones. DSLRs will remain useful for quite a number of professional applications, and let’s face it – if you want to look like you a serious photographer you’ll carry one of these things. It is an image thing…

The DSLR market is going to remain strong, but I don’t think you will see any new manufacturers – that I am sure of, because anybody that is doing anything new will be getting into some kind of mirrorless technology. And mirrorless is growing fast. I use the Panasonic G3 as my walk-around camera and it makes wonderful images. And each year there are more and more great lenses coming out for it. Mirrorless cameras are a bit expensive now, because the market is still small, but they will become more competitive. I think you are going to see more features, more integration with the web, etc. In terms of sensor technology, I don’t think we will see dramatic improvements, probably mostly small incremental improvements. I think going forward it will be more about features and integration with social media sites like Facebook, rather than simply about the underlying sensor technology. So even with mirrorless cameras, I see a big trend in making highly integrated products. It is certainly doable – right now I have to take a card out of the camera and load it into the camera, which is not as bad as compared to those days when you had to drive to a camera store twice and wait in line twice – once to drop off film and once to pick it up your prints or slides.

Currently, all the big companies are in the mirrorless market. Canon recently introduced the M mount mirrorless, and it was the last one to enter the market. It has a bigger sensor than the Nikon 1 mount, which is certainly an advantage for it. However, the initial lenses for the M mount that are not very impressive. But in the next two or three years, they’ll surely add a few good lenses. We are already seeing some pretty fine lenses coming up in the micro 4/3 space. One of my customers, Roger Cicala from lensrentals.com was raving about the new Olympus 75mm lens, which is extremely sharp.

Nasim: I fully agree with your view on the industry. I recently wrote an article on the future of digital cameras, where I share a very similar insight. Let’s talk about your company a little more, especially its future growth. Earlier when I came to your office, you indicated that you were moving to a different location. Are you expanding?

Norman: Yes, we are moving to new office space that will be a little less than twice the current size. We have a lot of work in industrial testing. We will continue to develop the GUI-based versions of the program, particularly Imatest Master. We have done a lot of things recently, for example, in looking at RAW images, RAW noise, etc. So we do quite a bit of testing in that area. Our primary near-term effort is supporting manufacturing, but that also means continued development of the GUI-based version, which you might think of as the front end of development side that leads to manufacturing. So our goal is to be vertically integrated in testing from the laboratory environment to manufacturing for an extremely wide array of applications. Our smallest cameras that we have been using are 160 pixels square and largest are 80 megapixel medium format cameras. So we have a versatile product that we will keep improving. We respond quite well to customer requests.

Nasim: You are also adding more staff as well?

Norman: Yes, we currently have 5 employees – 2 developers, 1 website admin that also helps out with printing, a business person and an administrator/bookkeeper. We are currently adding programmers, that’s where our biggest needs are. Ultimately, I need someone who can take over some aspects of my own work, which requires knowledge of imaging, photography, some image processing knowledge, Matlab programming, etc. We are also looking for a programmer with good knowledge of C++, C#, various development environments (Windows and Linux) to work on our programs.

We currently have strong realtime support for Aptina development systems. The name not many people might recognize, although it is a huge company that was a spinoff from Micron Technology. It is one of the world’s biggest image sensor chip makers. I think Sony is a little bit more familiar to people, because they make some sensors for Nikon DSLRs, but Aptina is a big name out there as well. We are also working with several automobile manufacturers. Specifically, we are helping them with fisheye-type rear-view cameras that are very distorted. We use a special chart for those measurements that is inversely distorted, allowing customers to use Imatest to measure sharpness and other optical parameters of lenses. On top of that, we are pretty involved with academia. There are cultural centers that use Imatest for testing out their scanners and cameras. We support university research environments as well. For example, one of our customers, Duke University, recently got a fair amount of publicity. They made a 50 gigapixel camera by combining a number of sensors and they actively use our product.

I also visited Google recently and I got to see their latest Street View backpack camera. One of my customers there integrates those cameras. You might have also heard of the Google’s Project Glass, which we are also a part of. We were involved in that project from the very beginning, but we didn’t know it since the folks at Google kept it a secret, and had a cover story.

Nasim: Wow, that’s very exciting. Seems like you are involved in many different projects!

Norman: Yes, we certainly are. I cannot wait to do more, I know we have a lot of great potential opportunities coming up in the future.

Nasim: Norman, thank you for your time and the opportunity for the interview once again. Talking to you has been a pleasure and I cannot wait to start using your product for our reviews at Mansurovs.com

Norman: And we thank you for the opportunity, as well as your trust in our product. Looks like your extra large SFR Plus chart is ready to be picked up now.

Nasim,

By using a scientific method you really set yourself apart from other reviewers. I know that I can trust your conclusions as they are backed by hard data. Many other sites don’t fully explain how they come to their conclusions. I think the latest review where you use this system to compare the 50mm 1.4 vs 1.8 using imatest was brilliant. It was the final nail in the coffin for me wanting that lens over my 1.8. Do you think you will run the same comparison on the 85mm 1.4g vs 1.8g? That would be just as good of a comparison as the fast 50s in my opinion.

This guy talks the same language a you lol… I just downloaded the trial for individual.

thks

FrancoisR, let me know what you think of the software, but I have to warn you, it is not easy to use :) Not because it is not a well-made or intuitive software, but because the lens testing process as a whole is far from being simple. Too many components, too many variables…

I will be posting an article on how I test lenses. Many readers are asking what the process is like and they are also wondering why I chose Imatest over the old traditional crop method.

Not easy to use you say? I called my number cruncher engineer friend and tried to put him on the case. Anyway I see challenge there. It reminds me of the radar antenna calibrating applications we had in ATC when I was data coordinator. I feel so retard now lloll.

Norman indicated right away that Imatest was not an easy product to use… It is a scientific tool, I guess it is expected :)